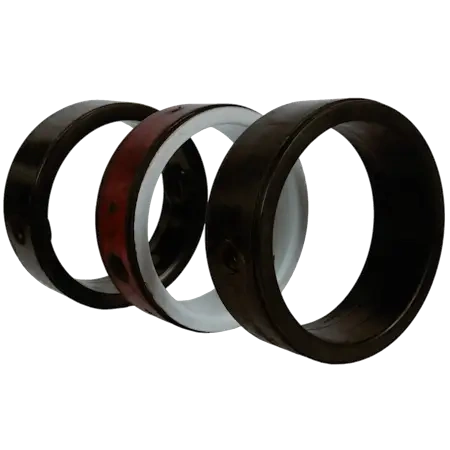

EPDM and BUNA-N (Nitrile, NBR) Spares

- Valve Usage:

- Sizes:

- Pressure:

- Temperatures:

- Butterfly Valves

- DN 50 – 600

- PN16

- -10°C to 120°C

Application

EPDM and BUNA-N (Nitrile, NBR) Spares are consistently available from Valvetech to cater for emergency and planned operations. A 30% Safety Factor for EPDM and Nitrile Liners can be added as these are made from more malleable rubber and tend to hug the disc more tightly. The Safety Factor for Teflon Liners is Zero as these are not malleable, which causes the disc to slide freely, so no extra Torque Factor is needed.

EPDM Liners

EPDM and BUNA-N (Nitrile, NBR) Spares are consistently available from Valvetech to cater for emergency and planned operations.

Ethylene Propylene Diene Monomer (EPDM) valve liners are used where reliable sealing and resistance to harsh environments is essential. A synthetic rubber known for its outstanding properties, including weathering resistance, UV resistance, and ozone resistance, EPDM Liners are suitable for valves that need to withstand exposure to outdoor elements and challenging climatic conditions.

EPDM Liners are used in:

- Water Treatment

- Chemical Processing

- HVAC Industries

- Food and Beverage

However, EPDM liners must not be used in systems with petroleum oils, hydrocarbons, alcohols, strong acids or strong alkalines due to the abrasive nature of oil in these media, as well as compressed air lines

With their exceptional durability and ability to maintain their integrity over extended periods, EPDM valve liners ensure optimal sealing performance, preventing leaks and reducing maintenance costs. Their flexibility and high-temperature resistance further contribute to their popularity, making them a preferred choice for a wide range of valve applications.

BUNA-N Liners

Butadiene Acrylonitrile (BUNA-N) Rubber valve liners are used where fluid resistance is critical. Known for its oil and fuel resistance, BUNA-N is ideal for applications where exposure to hydrocarbons and other petroleum-based fluids is common.

BUNA-N Liners are used in:

- automotive and aerospace

- oil and gas

- petrochemical industries

However, BUNA-N liners must not be used in systems with hydrocarbons as the solvents may attack the elastomer.

With their ability to withstand a wide range of temperatures and chemicals, as well as their tensile strength and tear resistance, BUNA-N Liners ensure long-lasting and reliable performance. With a proven track record in industrial settings, BUNA-N valve liners are a trusted choice for ensuring fluid control and efficiency in various valve systems.

Differences between BUNA-N, Nitrile, and NBR?

- BUNA-N (Butadiene Acrylonitrile Rubber) is a synthetic rubber co-polymer made from the polymerization of butadiene and acrylonitrile. The term “BUNA-N” is commonly used in the United States, especially in the context of gaskets, O-rings, and other industrial sealing applications

- Nitrile is a general term used to describe the family of synthetic rubber materials that contain nitrile groups (-CN) in their polymer structure. Nitrile rubber, too, is derived from the co-polymerization of butadiene and acrylonitrile

- NBR (Nitrile Butadiene Rubber) is the most widely recognized and commonly used term for this type of synthetic rubber. It is also a co-polymer of butadiene and acrylonitrile and is known for its excellent resistance to oils, fuels, and various chemicals.

Essentially, BUNA-N, Nitrile, and NBR all refer to the same type of synthetic rubber material that exhibit excellent oil and chemical resistance. The terms are used interchangeably, with regional and industry preferences accounting for the various naming conventions.

Specifications

Services

Petrochemicals and Petroleum, Refineries, Primary Energy, Agriculture, Water Works, HVAC

Industries

Water, Oil, Gas, Steam

Priority Media

Acetone, Acetylene, Air, Ammonium Bicarbonate, Animal Fats, Carbon Monoxide, Dry Cement, Dry Cement, Diesel Oil Fuels, Ethane, Ethylene Glycol, Dry Flour, Heptane, Hydrogen Gas, Nitrogen Gas, Oxygen Gas, Dry Plastics, Starch, Dry Sugars, Dry Sulphur Dioxide

For full Butterfly list, see Media Compatibility Table

Also Known As

Seat

Sleeve

Rubber

Download

Product Brochure

1MB, PDF

Please click the following PDF icon to download this specification sheet